Some Known Questions About Laser Scanning Solutions, Llc..

Table of ContentsThe Only Guide to Laser Scanning Solutions, Llc.All About Laser Scanning Solutions, Llc.Laser Scanning Solutions, Llc. Can Be Fun For EveryoneThe 7-Minute Rule for Laser Scanning Solutions, Llc.

In order to place a laser beam in two measurements, it is possible either to revolve one mirror along 2 axes - used primarily for slow-moving scanning systems - or to show the laser light beam onto two carefully spaced mirrors that are installed on orthogonal axes (https://www.viki.com/users/laserscann1ng/about). Each of both flat or polygon (polygonal) mirrors is after that driven by a galvanometer or by an electrical motor respectively

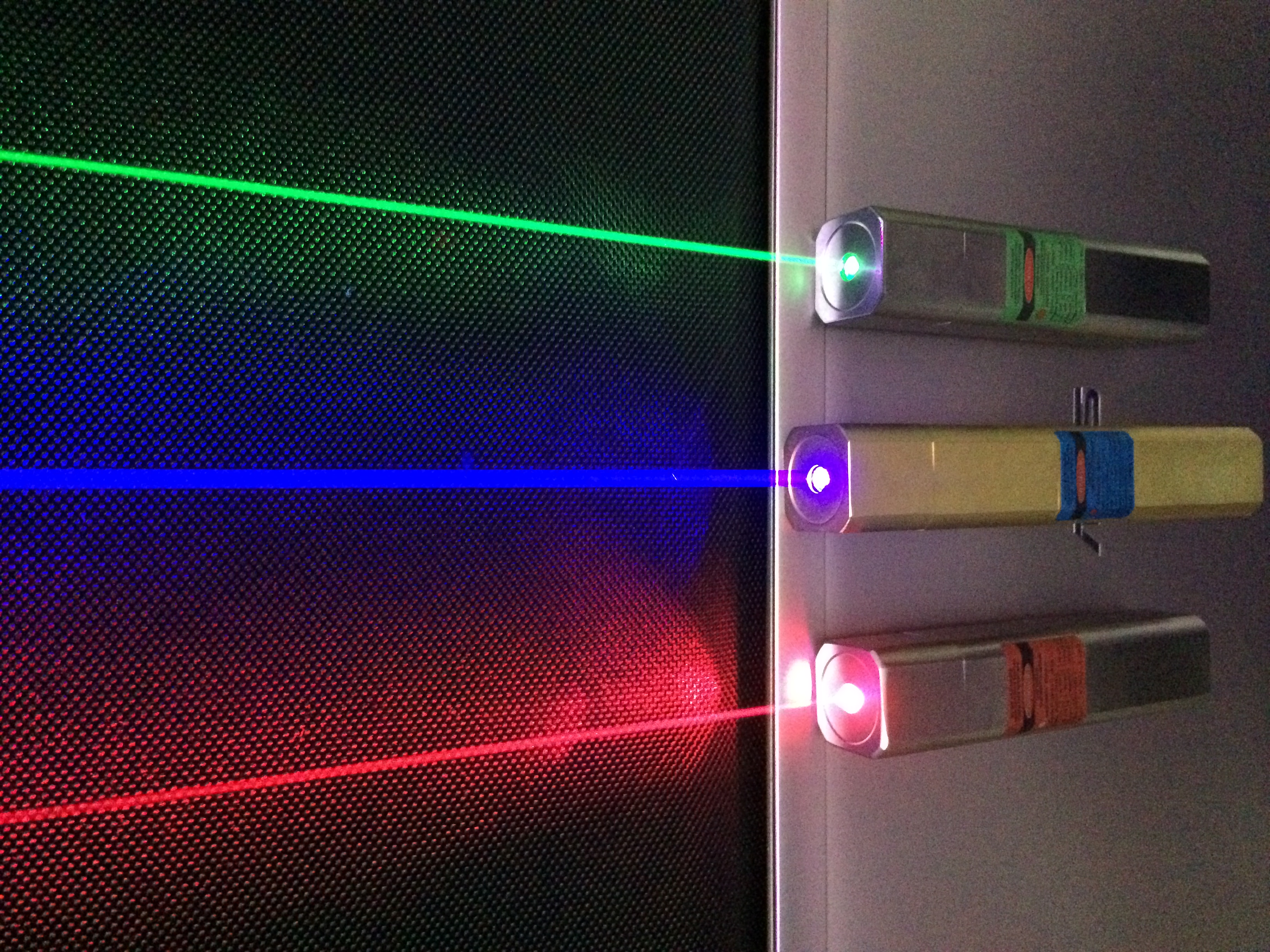

Some applications call for positioning the emphasis of a laser beam of light in three dimensions. This is accomplished by a servo-controlled lens system, normally called a 'focus shifter' or 'z-shifter'. Numerous laser scanners even more allow changing the laser intensity. In laser projectors for laser TV or laser displays, the three basic shades - red, blue, and environment-friendly - are incorporated in a solitary beam of light and after that reflected along with 2 mirrors.

Modern lasers can cut steel blocks with a thickness of 10 cm and even more or ablate a layer of the cornea that is just a couple of micrometers thick. The capacity of lasers to set fluid polymers, together with laser scanners, is used in quick prototyping, the capability to melt polymers and steels is, with laser scanners, to produce parts by laser sintering or laser melting.

What Does Laser Scanning Solutions, Llc. Mean?

That card converts the gotten vector information to movement details which is sent to the scanhead. This scanhead includes 2 mirrors that have the ability to deflect the laser beam in one level (X- and Y-coordinate). The third dimension is - if required - recognized by a particular optic that has the ability to move the laser's centerpiece in the depth-direction (Z-axis).

For these situations it is very important that the laser has as tiny a centerpiece as feasible (3d laser scanning). For enhanced laser scanning applications and/or high product throughput during production, scanning systems with even more than one scanhead are made use of. Here the software application needs to control what is done precisely within such a multihead application: it is possible that all readily available heads need to note the same to end up processing faster or that the heads note one solitary work in parallel where every scanhead does a component of the job in instance of large working locations

In these devices, a semiconductor laser beam is generally scanned with the aid of a resonant mirror scanner. The mirror is driven electromagnetically and is made of a metal-coated polymer. When an area transporter needs to dock to the spaceport station, it has to carefully steer to the proper placement. In order to identify its relative placement to the space station, laser scanners built right into the front of the area transporter scan the form of the spaceport station and afterwards identify, through a computer, the navigating commands.

The usages simply noted which are just a small tasting of laser scanning applications have extensively differing technical requirements. This consists of parameters like scanning speed, the size of the area or quantity that should be covered, the laser power entailed, the cost, size, dependability, and lifetime of the scanner, and a lot more.

An Unbiased View of Laser Scanning Solutions, Llc.

Depending on the nature of the job, galvanometer scanners are usually used in pairs. Specifically, in this case they are installed with their scan directions at appropriate angles per other. This allows the laser beam of light to get to any type of point in an see this website airplane. For numerous applications, specialized check optics, like an F-theta lens, are made use of to concentrate the light beam on the last surface.

Going back to 1960, when Theodore Maiman designed the first laser, this type of light has progressed into a device utilized throughout industries. From medical therapy to manufacturing handling, the power of lasers is made use of throughout a myriad of industries and for lots of kinds of applications. When most believe of lasers, the ubiquitous traffic signal lasers usually enter your mind.

Actually, there more than 8 kinds of lasers throughout 3 groups! In this blog, we'll explore each category of laser, what the category involves, utilizes for lasers, and eight different types of laser machines that comprise these categories - bim modeling. Light wavelength circulation map Solid-state lasers are kinds of lasers that use a strong product as its gain tool.

Unknown Facts About Laser Scanning Solutions, Llc.

When a laser diode shines light on the doped product, the neodymium atoms are delighted and give off light. This light is after that enhanced by the material and emitted as a laser light beam.

These laser kinds use gas as the medium rather of a solid or fluid. The four types of gas lasers are Carbon dioxide, He-Ne, excimer, and argon. CO2 gas lasers have the lengthiest wavelength compared to fiber, YAG, and YVO4.

Since of the lengthy wavelength, there is more warm transfer than various other lasers. CO2 lasers are frequently made use of for cutting materials.